What is the prospect of the granite machine-made sand market? As we all know, granite is known as "the king of rocks", its texture is hard and dense, high strength, weather resistance, corrosion resistance, wear resistance, low water absorption, beautiful color can also be preserved for more than 100 years, is a good building material. According to the feedback from the market for many years, the sand made of granite is of very good quality, uniform grain size and fine grain shape, which is in line with the standards of sand and stone for construction.

Generally speaking, granite general materials are around 60 yuan/ton, while granite machine-made sand prices are stable at 80-120 yuan/ton. At present, prices in Chongqing area are on the rise. From the general data, one ton of granite ≈ 0.7 to 0.8 tons of sand. If the production equipment configuration is reasonable, the whole production line is more broken and less ground, and the sand washing process is equipped with a fine sand recycling machine, the sand output rate will be relatively higher. In general, the profit of granite sand making is considerable, and the feasibility of investing in granite sand production line is very strong.

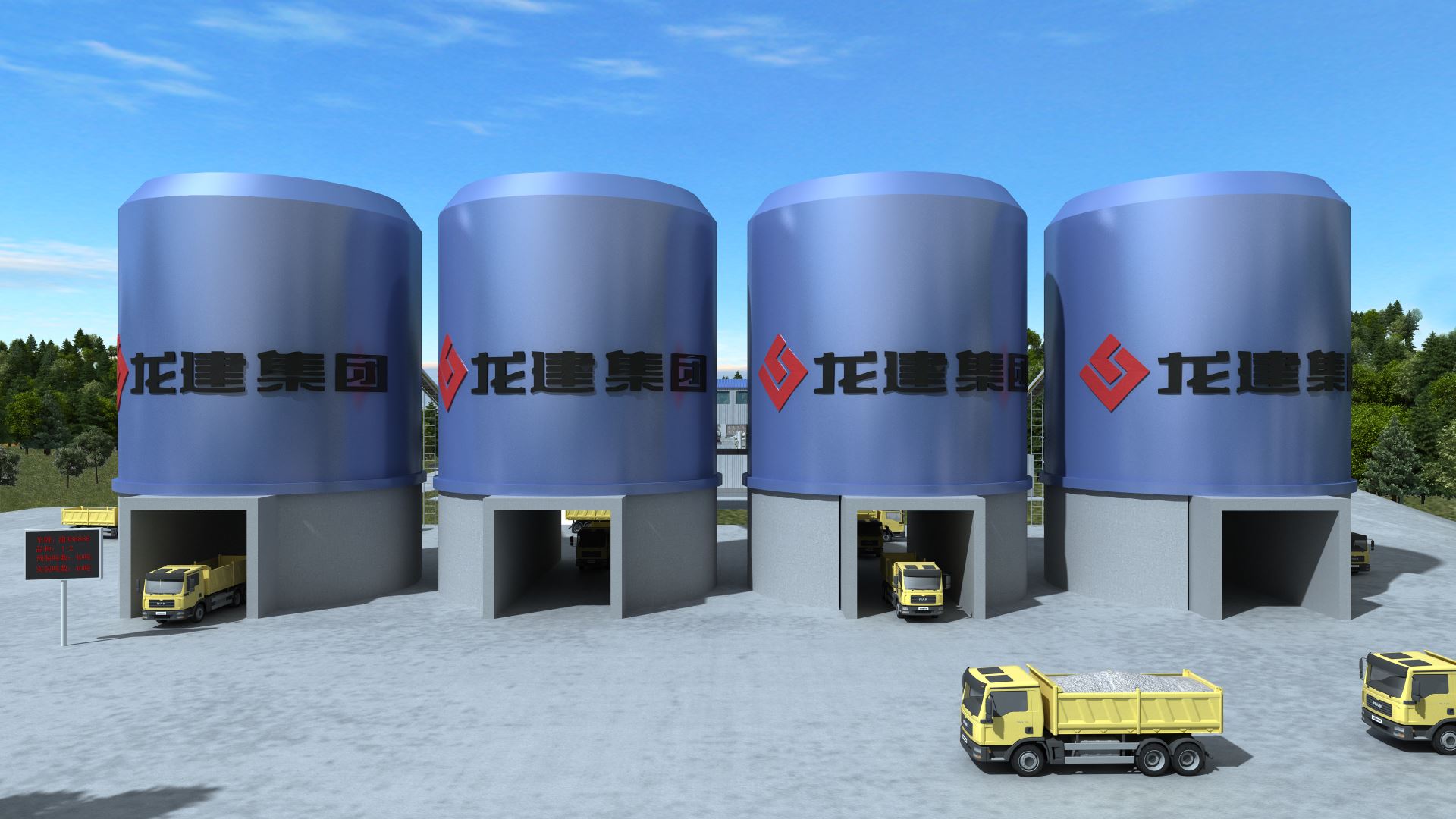

So, how do we buy equipment when we invest in a granite machine-made sand production line? Longjian Group has focused on mining machinery for nearly 30 years. Here we recommend the following equipment for you: jaw crusher, cone crusher, plastic sand making machine and its pulse bag dust collector, powder separator and other auxiliary equipment.

1. Jaw crusher. For the characteristics of granite such as high hardness, the jaw crusher with large crushing force, high processing efficiency, simple structure, stable and strong, and reliable operation is recommended as the initial crushing equipment. According to different jaw crusher models, the production capacity can reach 15 times. ~1500 tons.

2. Cone crusher. The hydraulic cone crusher is used as the second-breaker equipment, which can directly process the granite into crushed stone that meets the feed particle size of the sand making, and the output particle size is uniformly adjustable. Moreover, the production capacity of the equipment is large, and maintenance and adjustment are convenient.

3. Plastic sand making machine. The crushing cavity and deep cavity impeller design made of stone iron can effectively increase the material throughput by 30% while making sand. The impact crusher (shaping sand making machine) makes the granite sand granules more excellent in a round shape. Angled. Because the equipment is hydraulically opened, operation and maintenance are more convenient.

On-site production line of African Tanzania granite machine-made sand under Longjian Group:

At the same time, according to the user's output requirements, configure the vibrating feeder, circular vibrating screen, sand washing machine, dust collector, powder separator, belt conveyor and other auxiliary equipment.

In summary, according to different production line configuration schemes and equipment combinations, the price of investing in granite machine-made sand production lines is generally around 500,000 to 1 million, and the price of environmentally friendly production lines will be slightly higher. Under the conditions of the same output and the same configuration, the price investment of the wet production line will also be higher than that of the dry method. If you want to know the specific price of granite machine sand production line equipment. Welcome to consult online customer service, or call 400-023-0808. We will serve you wholeheartedly.

-

Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line

Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line -

The 2022 Spring Festival holiday notice of Longjian Group

The 2022 Spring Festival holiday notice of Longjian Group -

Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021

Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021 -

Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities

Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities -

.png) Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration"

Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration" -

How to create green mines and green factories?

-

In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province

In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province -

Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association

Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association